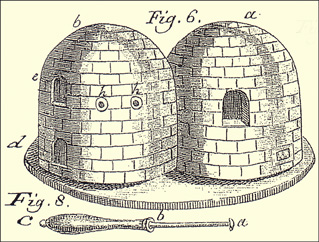

...In Székelyvarság the older generation know it as: “frog salt“ and potash is needed for it, in other words: small “salty” crushed stones and a melting material (with potassium) that is made of potash Even further back in time, it was thought that ground basalt or fine, white river sand, soda, lime and great heat were necessary to melt it. Thus quartz, meaning silica oxide and alkali metals and calcium to make the framework – just as in the bones. To paint it you need metal oxides: manganese for purple, cobalt for blue, iron for yellow, green and blue in the melt. During the volcanic processes a natural glass, Obsidian is made. In it are the three main components: silica, alkali metals, and fire at 1200-1500 degrees Celsius, when the mixture becomes syrup, like dripping honey...

The result is not a crystal and cannot be categorized as a solid material either. In chemistry, materials that are similar to glass can only be called “glass-like” materials. Péter Székely at an unveiling of a sculpture said: “Since scientists have to this day not managed to solve the secret of light, they have left room for sculpture.” We glass-blowing artists are lucky as well, that we do not know exactly what glass is. In certain places in Africa, the blacksmiths and glass makers, “furnace people”, can only work outside the village And those who manipulate fire are in some way connected with the Gods. Well then, once upon a time there was glass: in Mesopotamia for at least five thousand years, in Egypt and after Rome, everywhere. The Avars and the Carolingians had glass and then we in Hungary too. At the mines they kept a mixture of nitric acid and hydrochloric acid in bottles so as to be able to divide gold. Where there was a mine, there was a forest, wood for burning, potash; that is why there could be furnaces and glass-blowing as well In the beginning, the glass blowers made glasses, bottles, goblets and jugs for the noblemen. But later they worked for the people in the area, not only for the noblemen, but for the wealthier citizens and eventually for the peasants too. In the glass-blowing workshops of the monasteries, they made bulls eye glasses for windows and churches and they blew other items as well. After the fall of the Roman Empire these places kept the knowledge of glass-making. “When someone looks into a fire all bad thoughts go away” say the American Indians. When we use our glass objects we can remind ourselves that they were made with fire and sweat, that the knowledge has been passed on by many people from one to the other, from grandfather to father to son, through many thousands of years...

/ Gergely Pattantyús – Blaze Mine Glass Art Foundation/